Expression

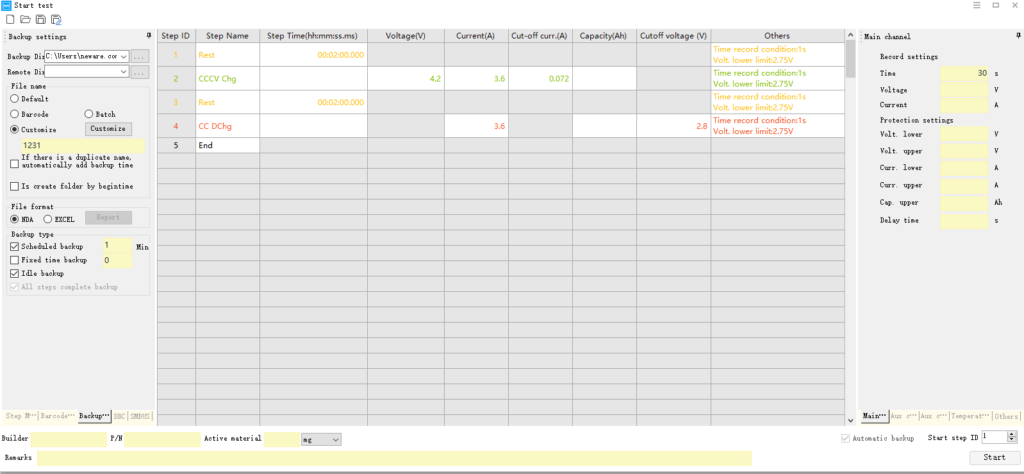

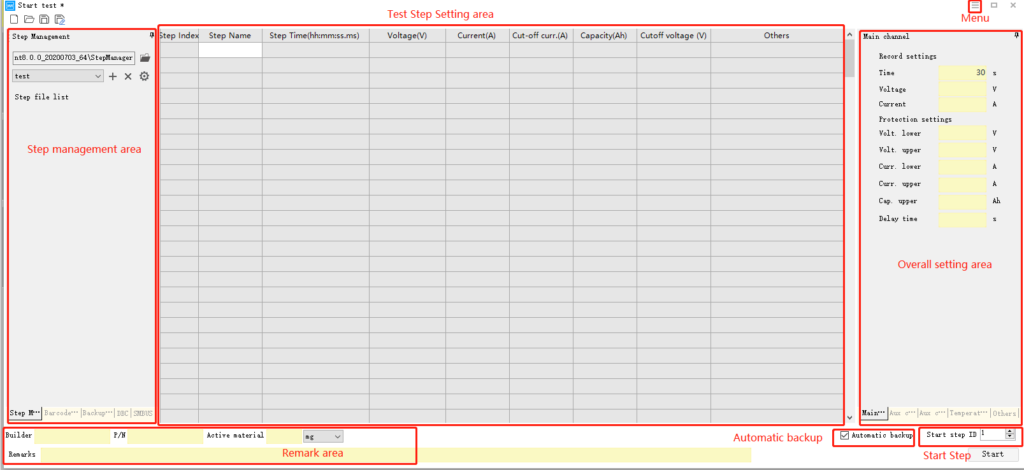

The difference between Test Step Setting and Expression:

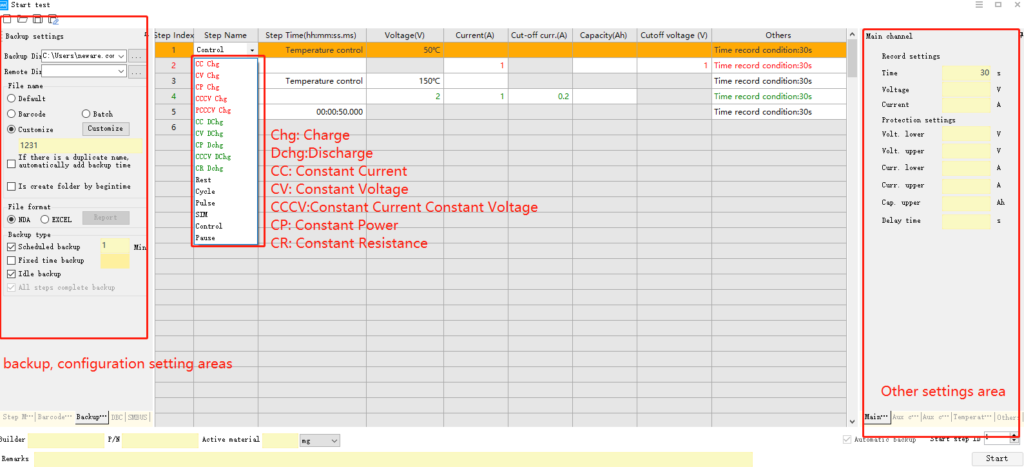

Test Step Setting is for saving test build parameters and the invocation of following Test Step Settings and Expressions.

Expression is an user-made inequation as the cut-off condition of a Test Step. When the setting of the inequation is satisfied, the test will go to the assigned Test Step.

Remark: Expression only works in BTS8.0(middle machine version).

1 Setting

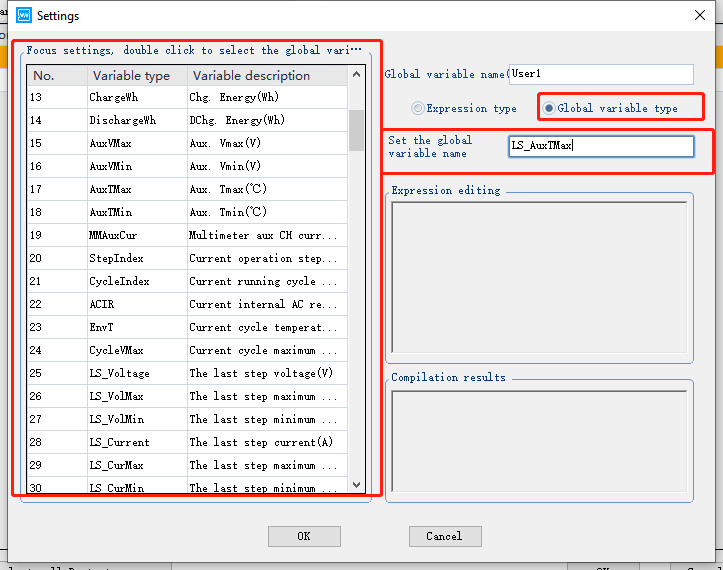

There are two types of setting, expression type and global variable type.

The name of Global variable means exactly the same as its function.

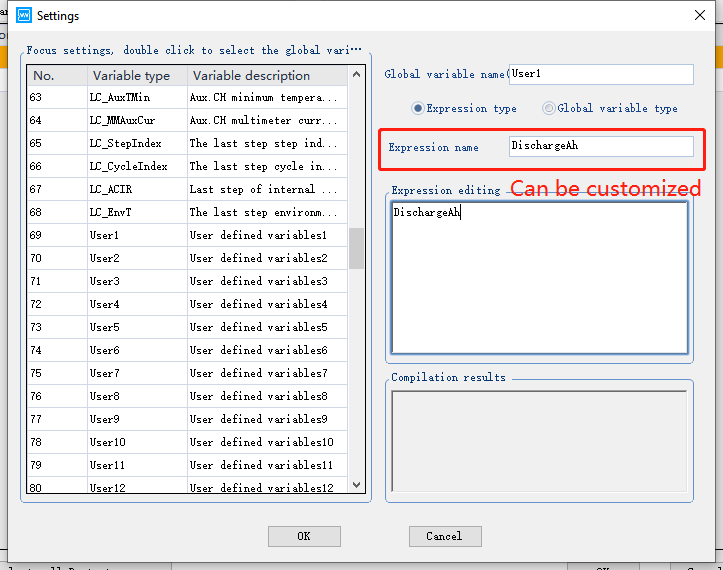

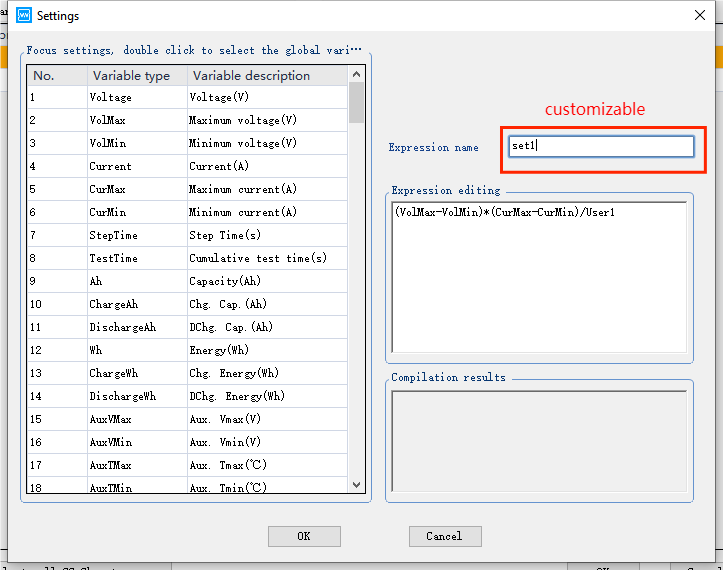

The Expression name which can be customized does not have an actual meaning.

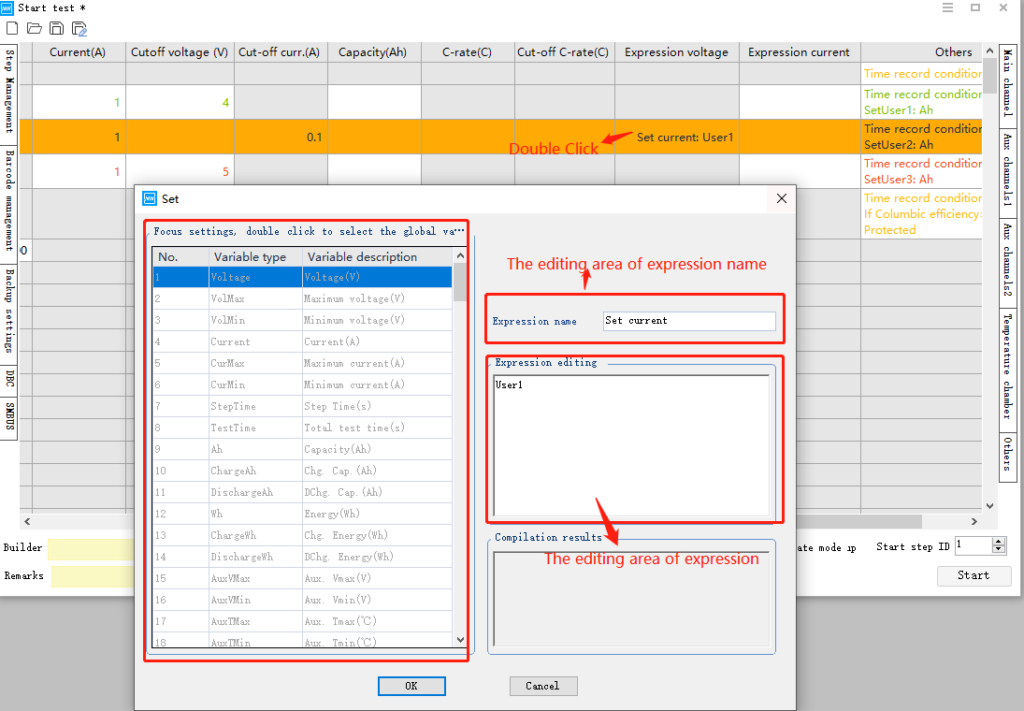

Expression Setting Steps:

-

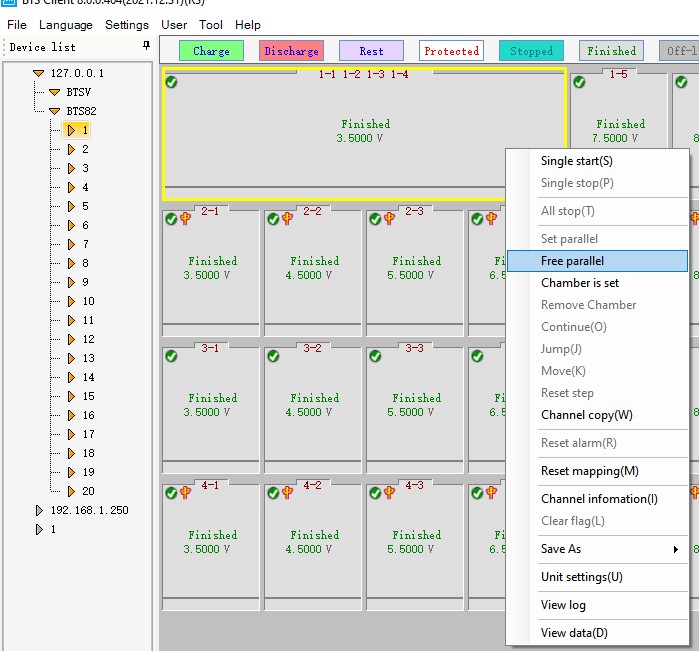

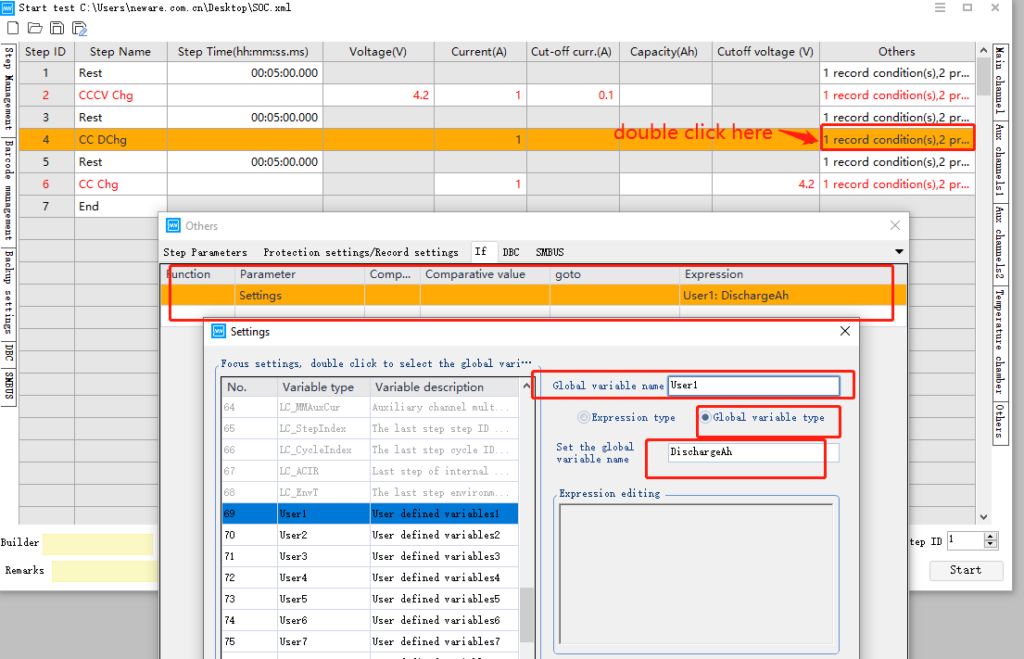

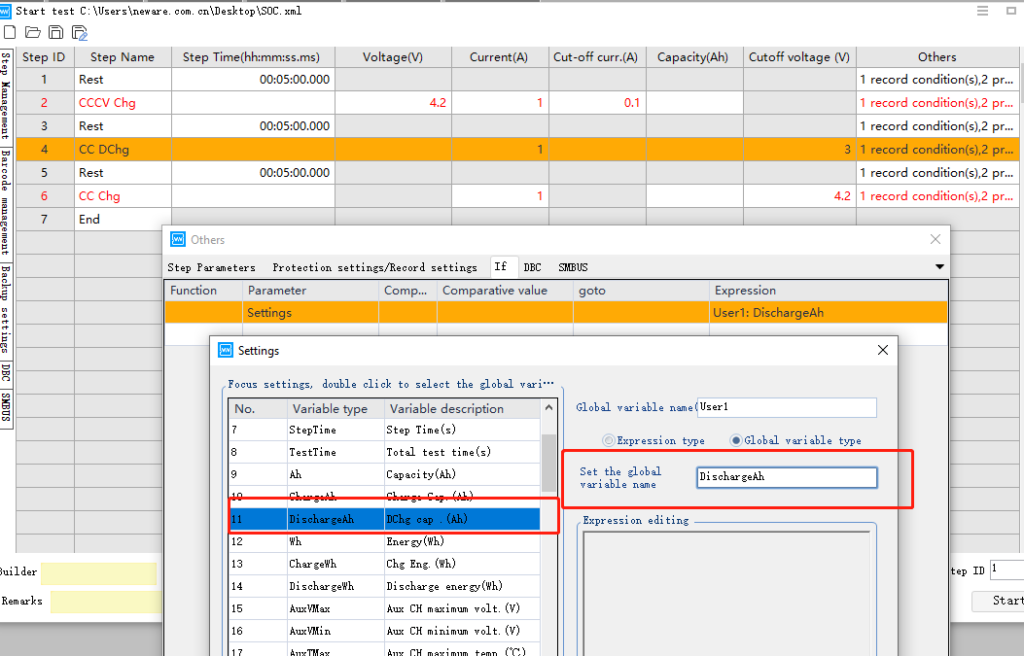

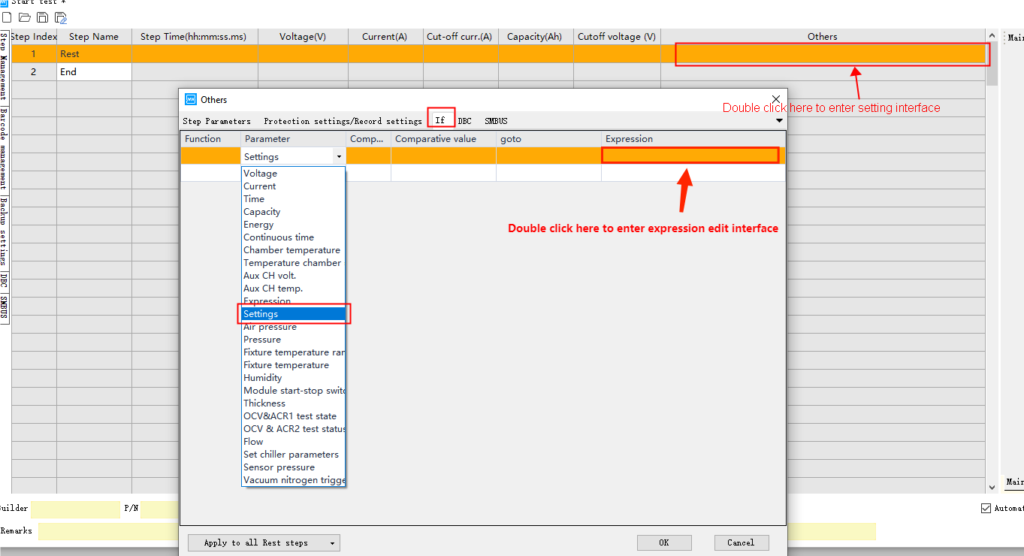

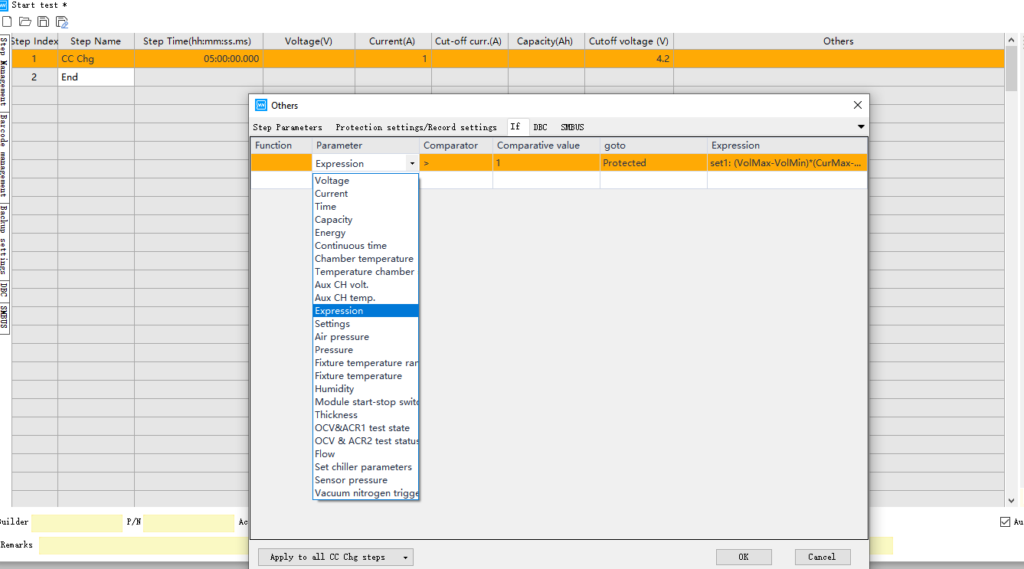

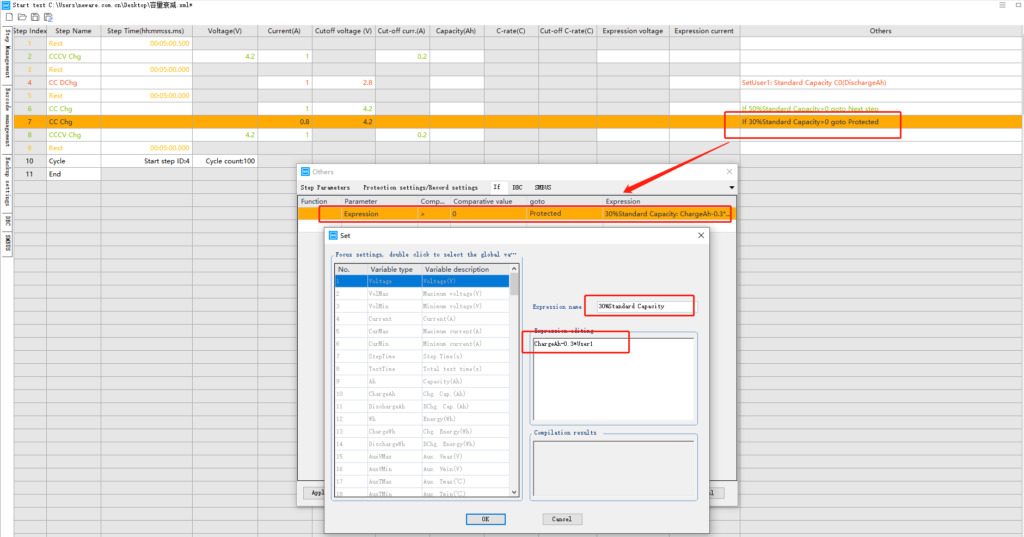

Click ‘other’section for a certain test step → go to ‘if’ → select ‘settings’

-

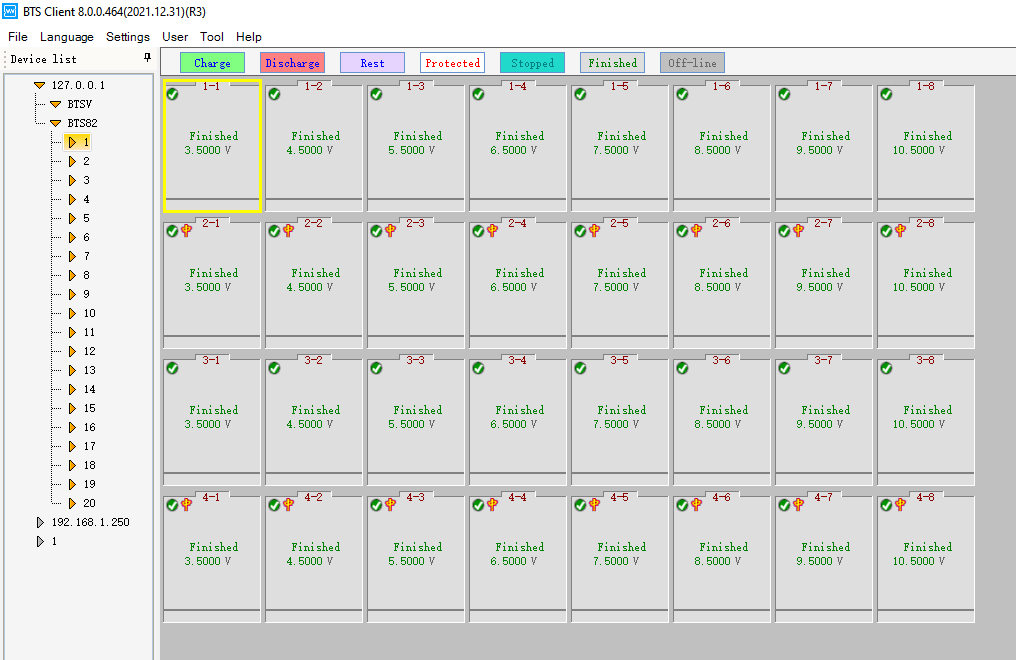

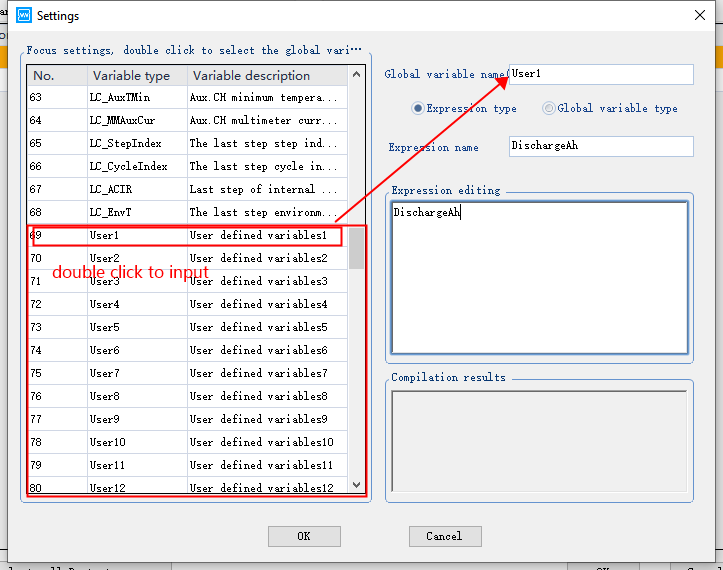

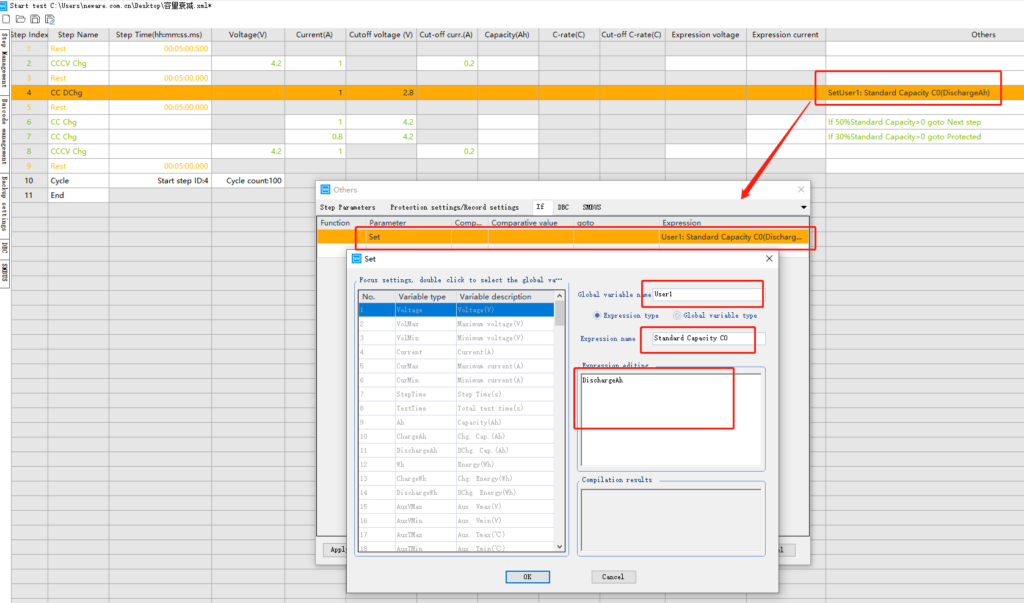

To customize the global variable name, selecting from User1~User50. Double click the parameter to input to avoid the manual input error.

-

Expression name can be customized

-

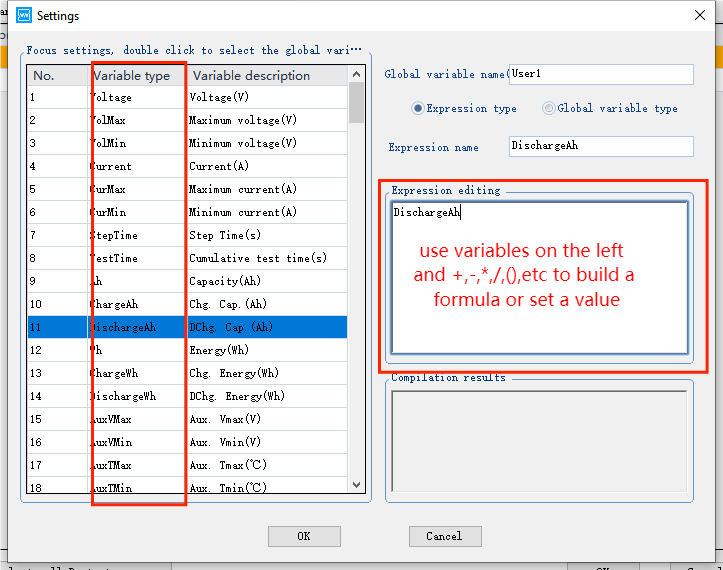

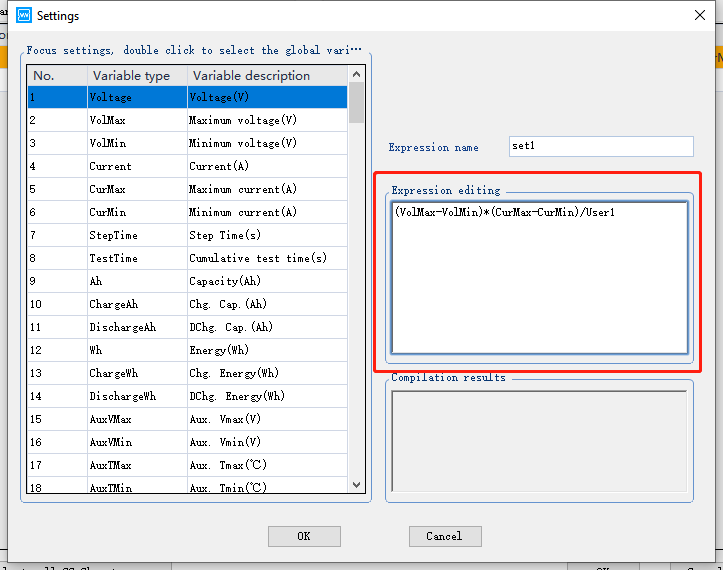

Expression editing

Notice:

-

Notice the unit of each variable

-

“75*Ah”can not be inputted as “0.75Ah”

-

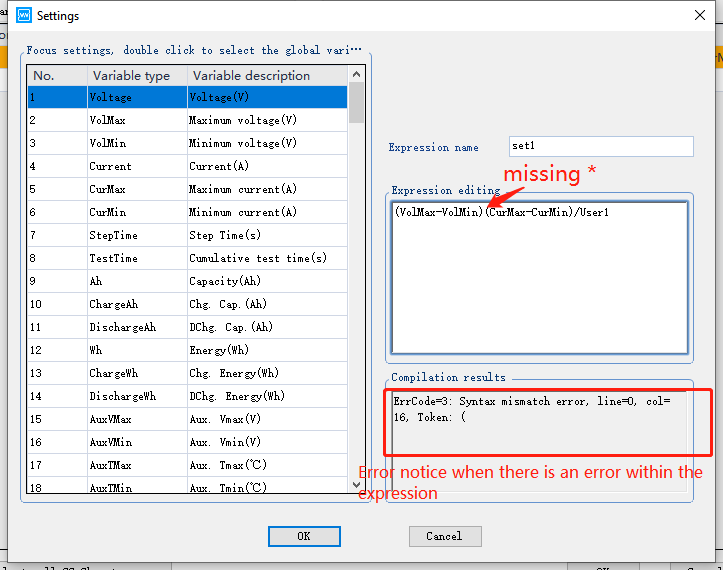

For example, “3*Ah*(VolMax-VolMin)*(CurMax+CurMin)/User2” can not be inputted as “3Ah(VolMax-VolMin)(CurMax+CurMin)/User1” and “*” can not be missed while inputting.

-

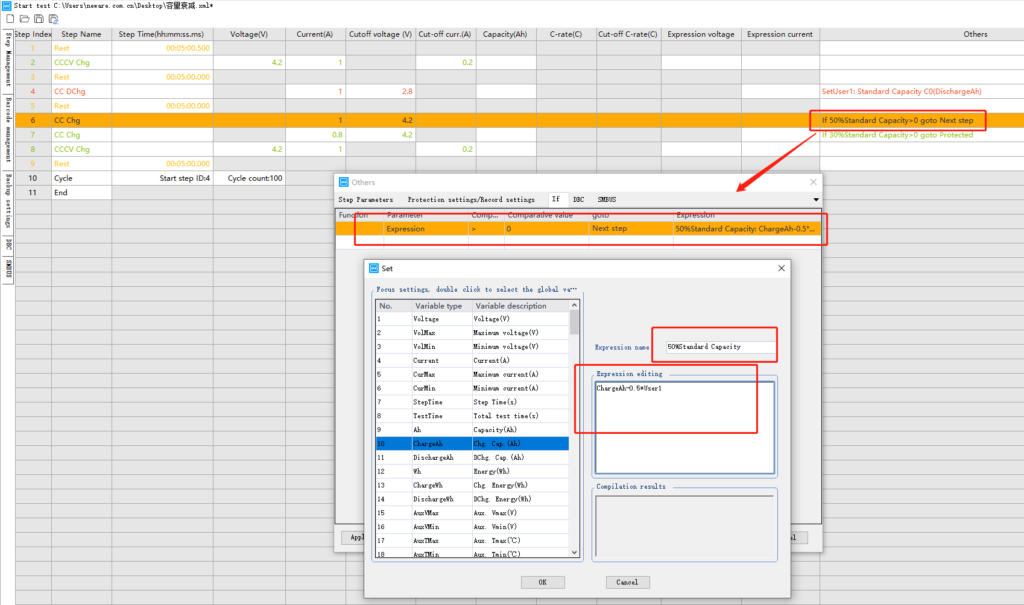

When a expression has a customized variable like point 3 indicated, the “User2”has to be set a formula or a value

-

When select global variable type, the global variable name to be set can only be selected from the global variable.

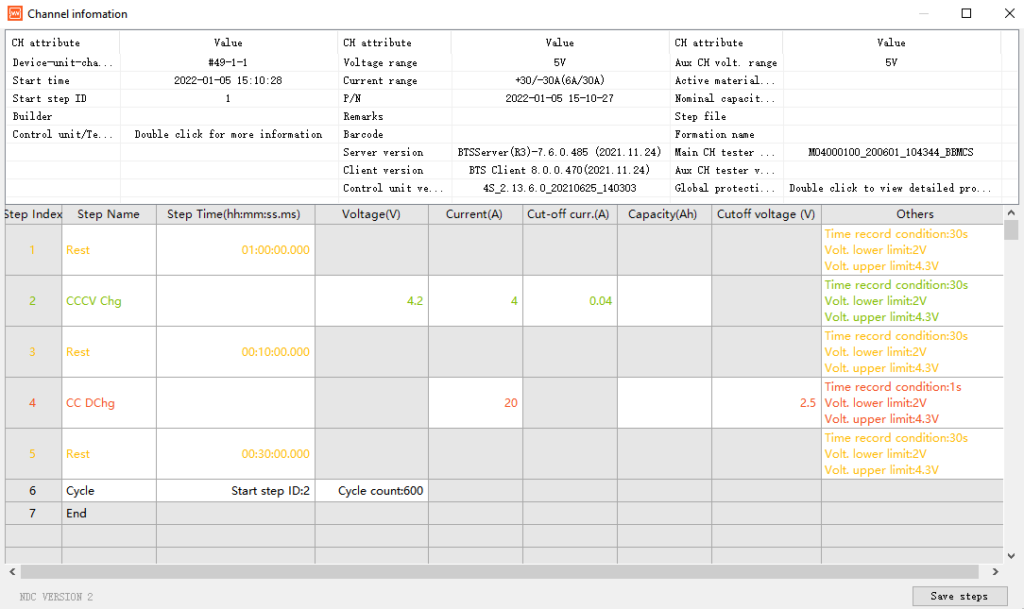

2. Add Expression

Add expression function is for user to edit the expression as the cut-off condition of certain test step.

-

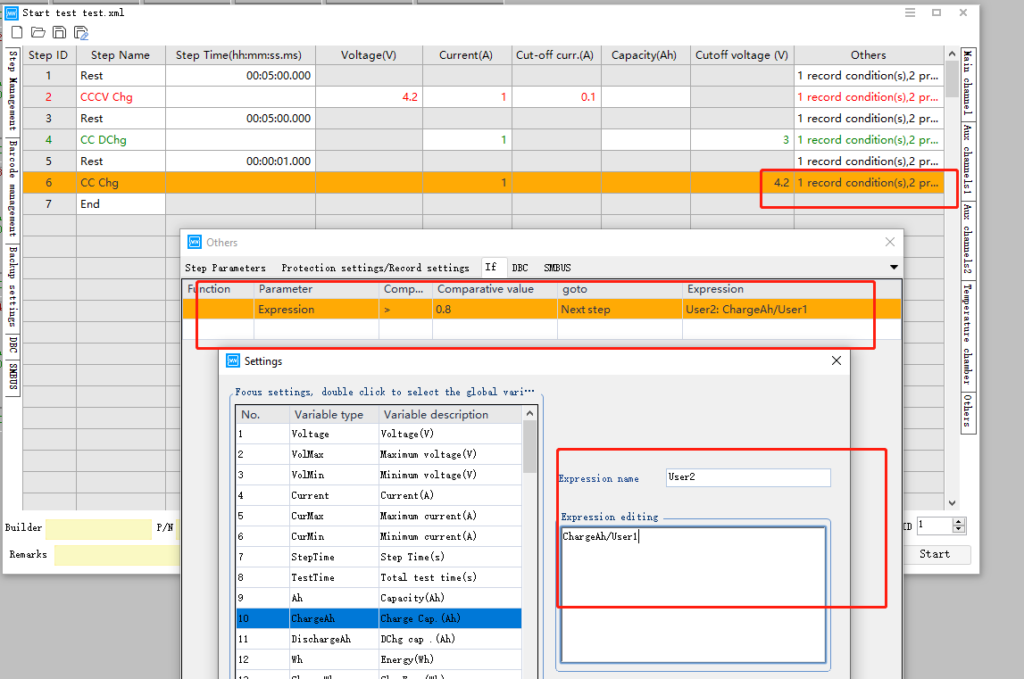

As picture below shows, it adds a expression for cc charge step, the comparator, comparative value and goto can be set based on the application.

-

The express name is named by the user.

-

Expression editing is customized expression.

Notice: “*” can not be missed, for example, “3*Ah*(VolMax-VolMin)*(CurMax+CurMin)/User2” is correct and “3Ah(VolMax-VolMin)(CurMax+CurMin)/User1” is wrong.

-

Expression meaning reference:

Voltage:Current voltage of the channel

VolMax:Highest voltage of the channel under current test step

VolMin:Lowest voltage of the channel under current test step

StepTime: Running Time of current test step

Test Time: Time started from the start of the test

Ah:the accumulated capacity value start from the start of the test

Wh:the accumulated energy value start from the start of the test

3.Expression Current and Expression Voltage

The steps supported by the expression current: constant current charge, constant current discharge, constant current constant voltage charge, constant current constant voltage discharge.

The steps supported by the expression voltage: constant voltage charge, constant voltage discharge, constant current constant voltage charge, constant current constant voltage discharge

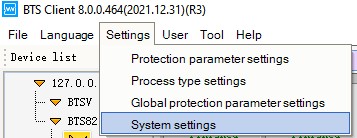

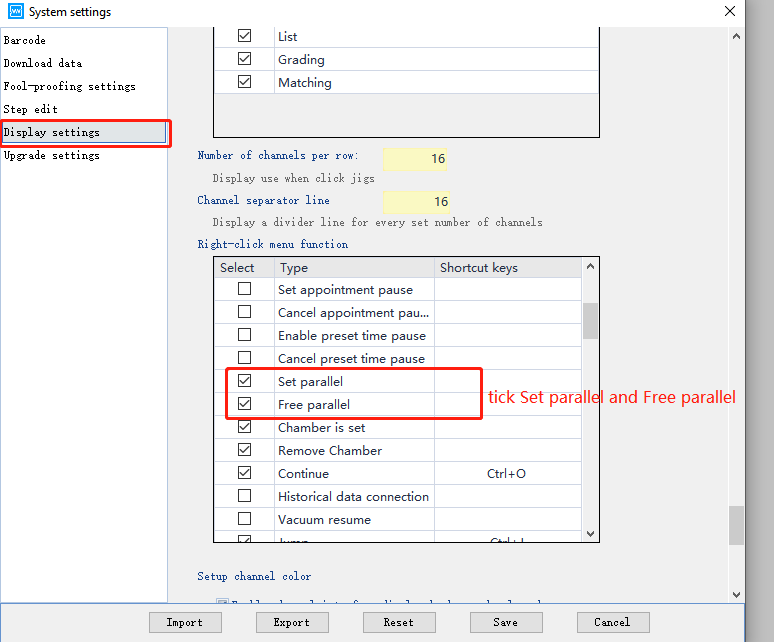

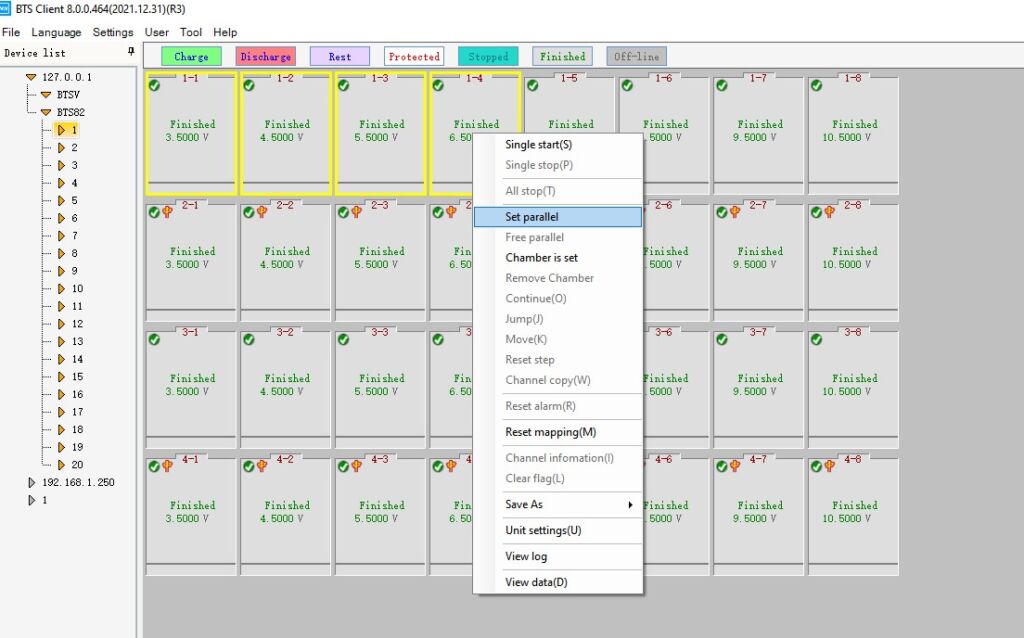

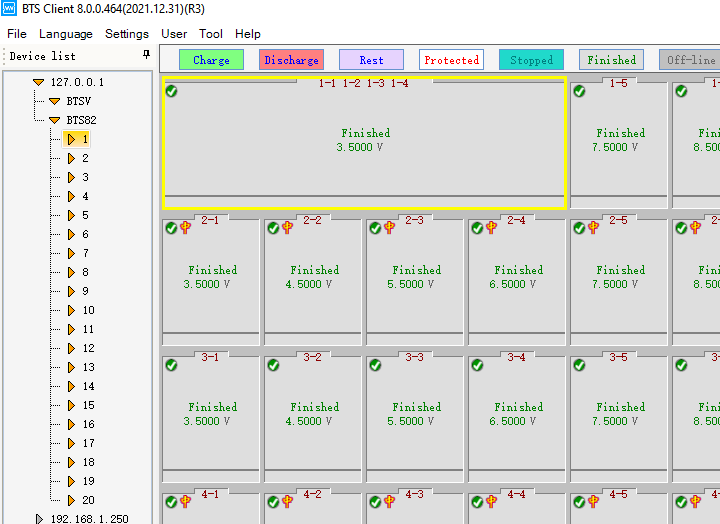

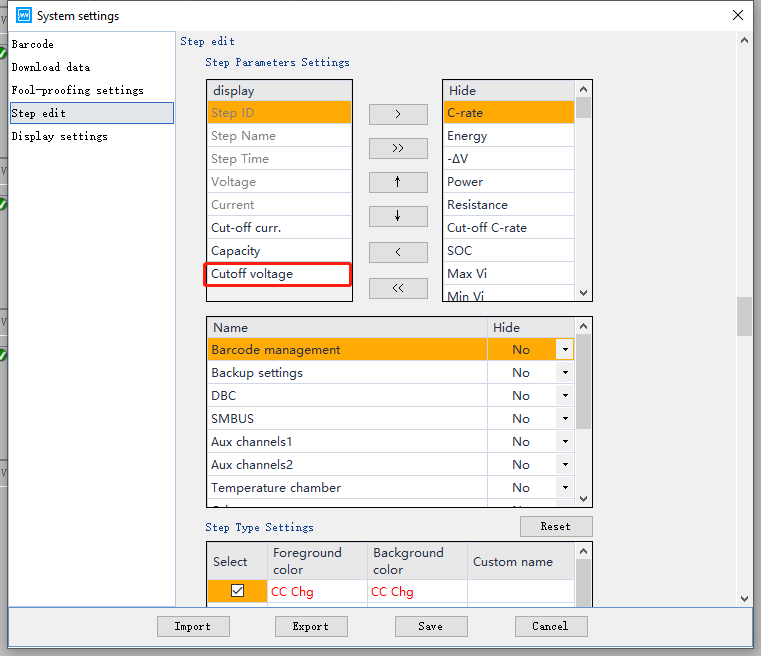

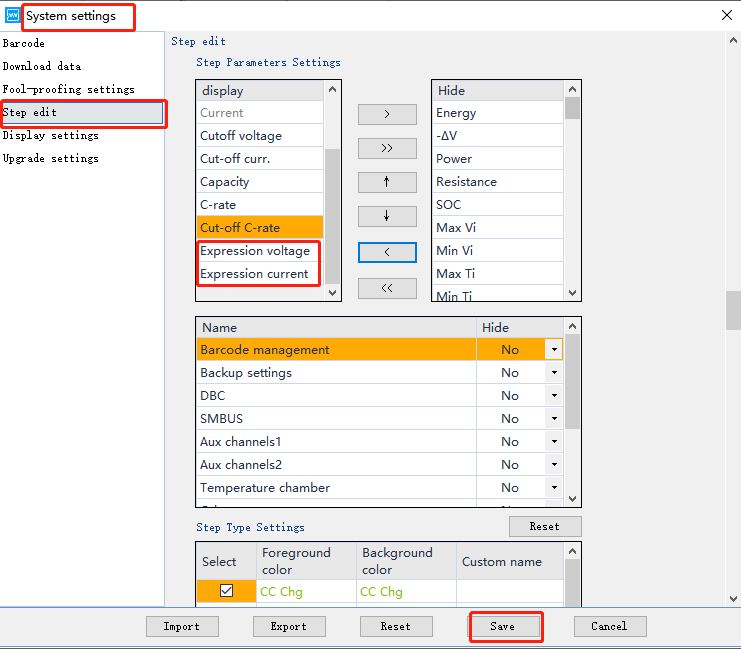

The expression current and expression voltage can be changed from hidden to displayed via <System settings>.

See the expression description for editing details on expression current and expression voltage

1. Expression current

Meaning: You can set the expression to limit the current value of the running step.

2. Expression voltage

Meaning: You can set the expression to limit the voltage value of the running step.

4.The meaning of variable of Expression

-

Voltage: Voltage(V)

-

VolMax: Maximum voltage(V)

-

VolMin: Minimum voltage(V)

-

Current: Current(A)

-

CurMax: Maximum current (A)

-

CurMin: Minimum current (A)

-

StepTime: Step Time(s)

-

TestTime: Total test time(s)

-

Ah: Capacity(Ah)

-

ChargeAh: Chg. Cap(Ah)

-

DischargeAh: DChg. Cap(Ah)

-

Wh: Energy(Wh)

-

ChargeWh: Chg.Energy(Wh)

-

DischargeWh: DChg.Energy(Wh)

-

AuxVMax: Aux.Vmax(V)

-

AuxVMin: Aux.Vmin(V)

-

AuxTMax: Aux.Tmax(℃)

-

AuxTMin:Tmin(℃)

-

MMAuxCur: Multimeter aux CH curr.(A)

-

StepIndex: Current operation step index

-

CycleIndex: Current Running cycle index

-

ACIR: Current internal AC resistance(Ω)

-

EnvT:Current cycle temperature(℃)

-

CycleVMax: Current cycle maximum voltage(V)

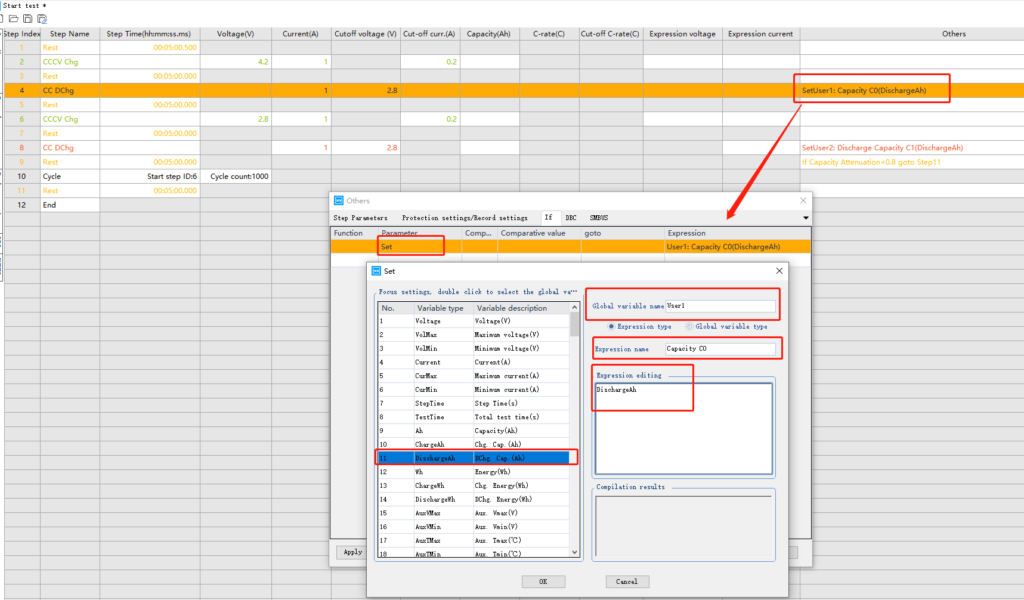

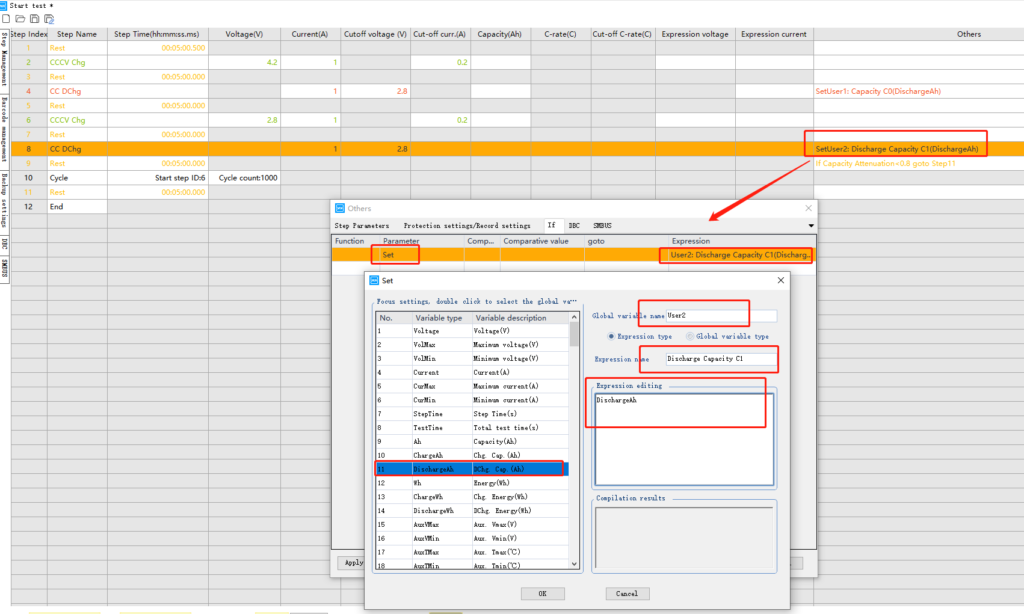

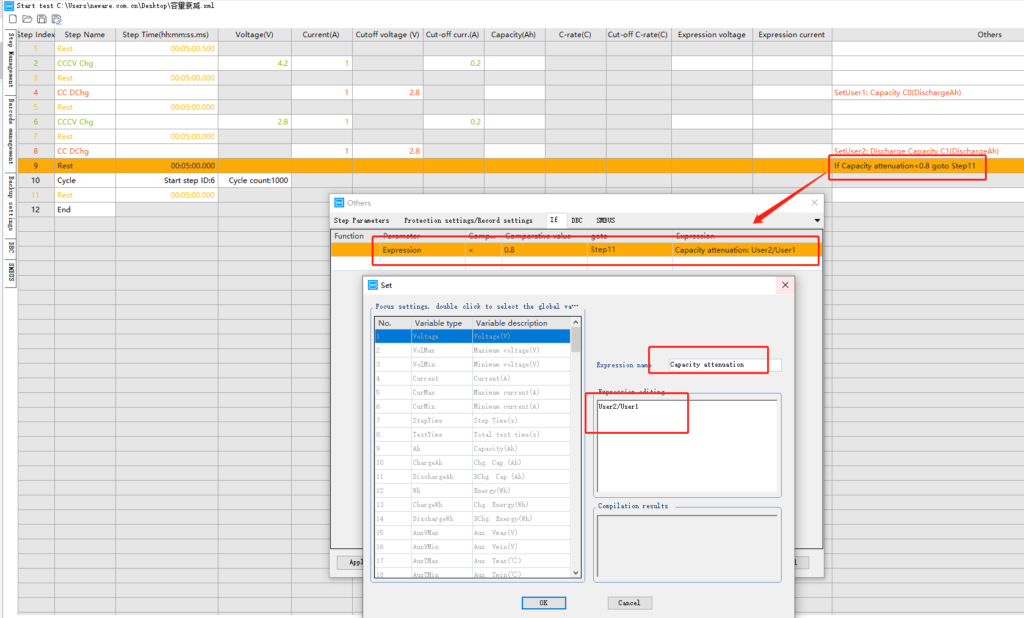

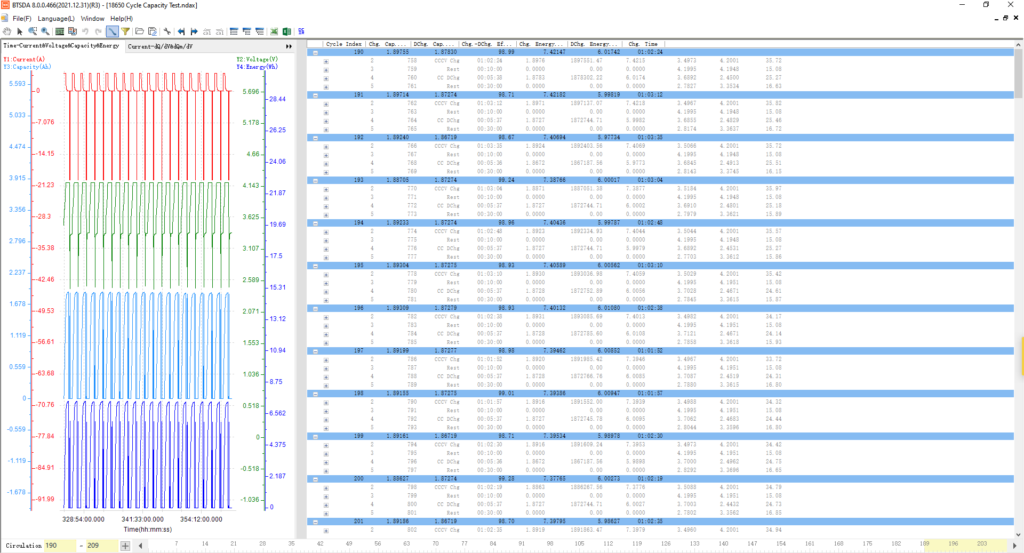

5.Samples

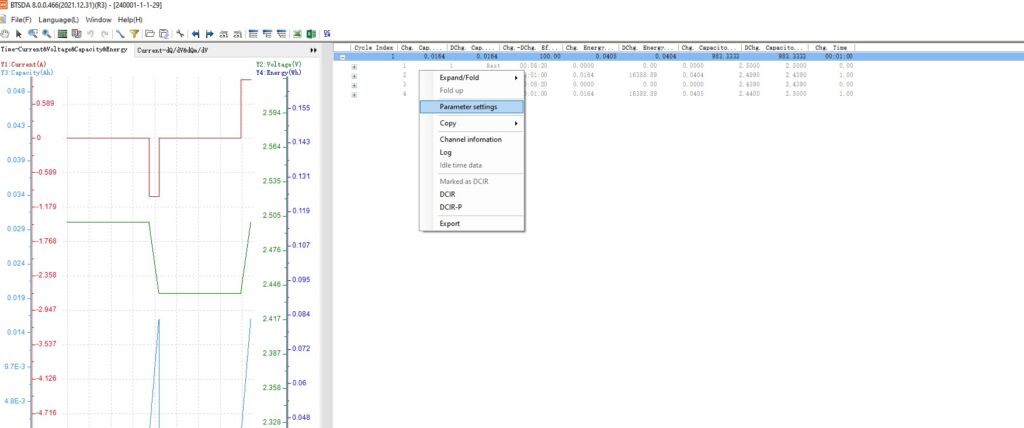

1. Capacity Attenuation

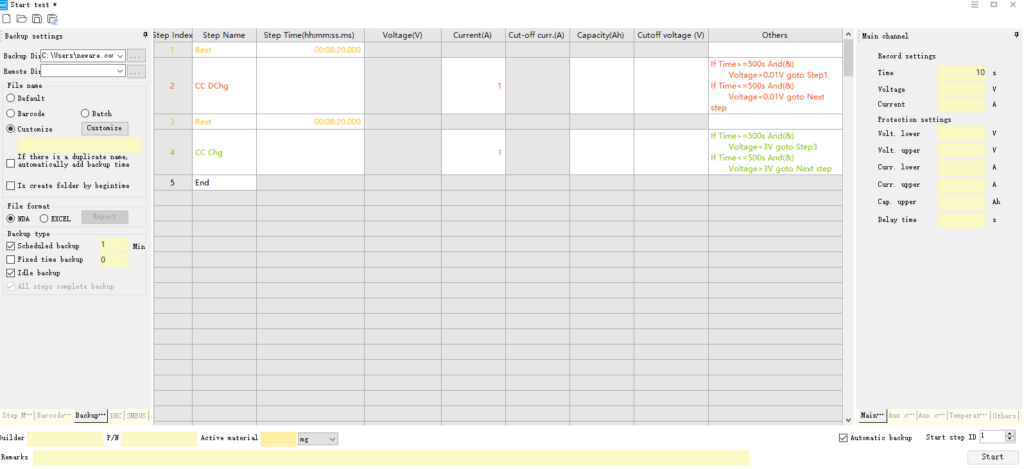

2. SOC

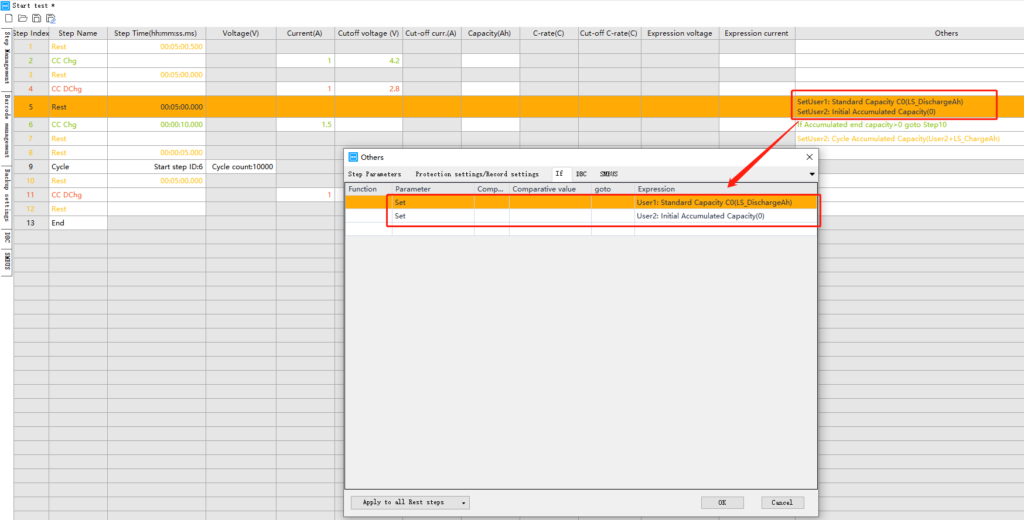

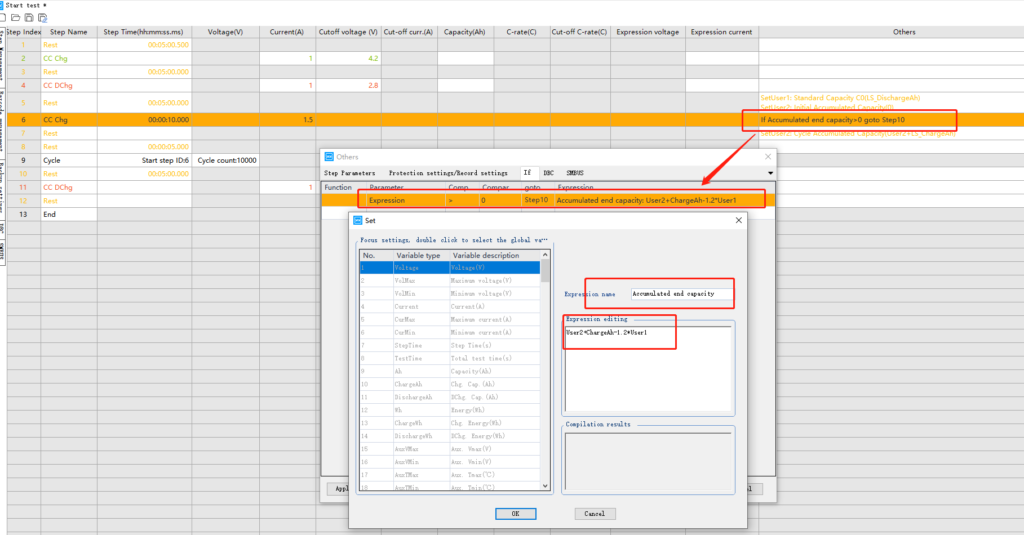

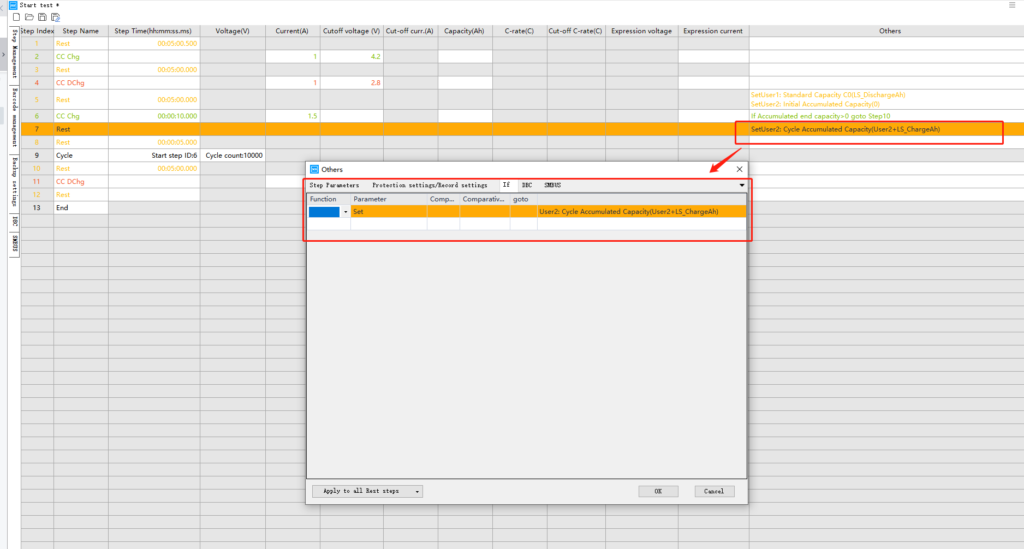

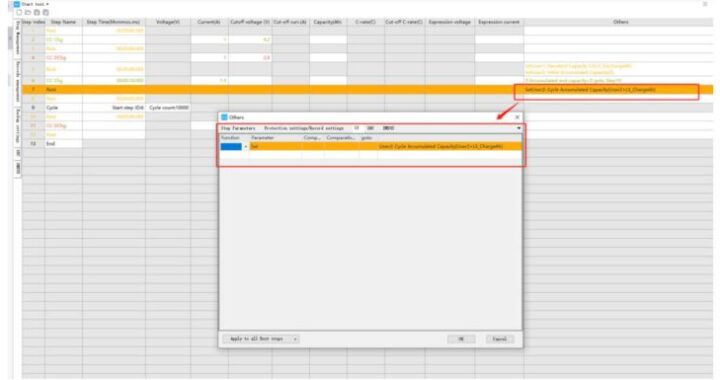

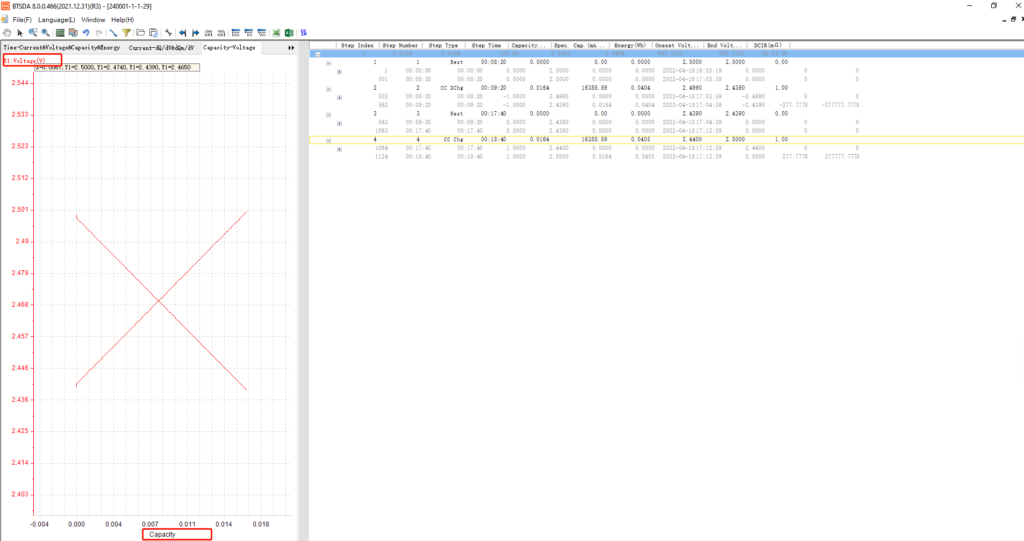

3.Accumulated capacity